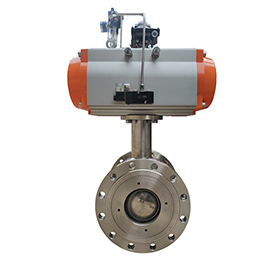

Pay attention to the following points when operating the integrated high-temperature ball valve:

1. Since multi-layer soft stack sealing ring and hard stack sealing ring are fixed on the valve plate, when the valve plate is normally opened, the medium forms positive flushing on the sealing surface of the metal plate. The sealing performance will be directly affected after the sealing belt is refined.

2. Due to structural conditions, this structure is not suitable for valves with diameter less than DN200, because the overall structure of the valve plate is too thick and has high flow resistance.

3. Due to the three eccentric principle, the sealing between the sealing surface of the valve plate and the valve seat depends on the torque of the transmitter, which presses the valve plate against the valve seat. Under the condition of positive flow, the higher the medium pressure, the tighter the seal extrusion. When the medium in the flow path flows backward and the medium pressure rises, the unit positive pressure between the valve plate and the valve seat will be lower than the medium pressure, and the seal will start to leak.

The above are the points to be noted when operating the integrated high-temperature ball valve. You can learn about it. If you need a friend, you can consult Wenzhou Jiadian Machinery Manufacturing Co., Ltd.